Pro Steel Super Structure

Roof Depot Ltd has been designing, manufacturing and Installing Light gauge (cold-formed steel) Roofing Structures for the past 17 Years. In 2008 we successfully completed 157 housing Units for Nipdec Ltd. (Riverwood Gardens D’Abadie) and as they say the rest is history.

With this knowledge and Experience we have expanded to offer a complete steel framed Housing system using Light Gauge Steel, which we have coined; PRO-STEEL STRUCTURES.

PRO –STEEL BUILDING SOLUTION

We have developed a pre-engineered housing kit that reduces the building time by 50% and reduces the labor cost significantly. Our Custom-Manufactured, Light Gauge Steel Framing Solutions offers numerous advantages in construction speed, strength, versatility and operational efficiencies.

THE HOUSING KIT INCLUDES:

- Steel Super Structure (All the External, Internal walls, Floor Joist and roof Framing)

- Roofing Materials (Sheeting, Flashings, soffit, guttering, radiant barrier)

- Building Wrap Insulation

- External Wall ½” Concrete Cladding Panels

- Aluminum Windows and Doors.

- Anchoring, Fasteners & Sealants.

THE CUSTOMER REQUIREMENTS

- To Supply detail drawings & detail scope of works.

- To Prepare Level, smooth, plump Concrete Foundation.

HURRICANE AND EARTHQUAKE DETAILS

AT a minimum our structures are designed to withstand earthquakes measuring 8 on the Richter scale and at least a category 3 hurricane winds. These structures can even withstand stronger winds to seismic depending on our clients requirements. These inputs will alter the design, the anchoring and fastening system along with the size, thickness and span of the steel.

SMARTER + FASTER CONSTRUCTION

The Pro-Steel building structure is the most economical way to build. In addition; there is tremendous COST SAVINGS to be derived such as; Speed Of Erection, Reduce Labour Cost, getting into your home earlier; less clean up, no warping so finished walls and ceilings are accurate to the MM so there’s minimum wastage, not to mention our system is stronger than alternative construction methods.

All Our Steel conforms to ASTM standards and the system is manufactured to the highest building standards and codes. All materials used in the design are coated with galvanize Zinc G90 275 gms/ SM and have a Tensile Strength of 50000 PSI which is TRINIDAD AND TOBAGO BUREAU OF STANDARDS (TTBS) CERTIFIED.

Benefits of Pro Steel Building Solution

Simple & Easy.

- Steel is lighter, stronger and straighter.

- Steel’s quality is consistent. No bowing, bending, warping, twisting ensuring no long term movement problems with the framing and trusses.

- The wall frames and roof trusses can be positioned and screwed together without needing access to the power grid.

- Prefabricated frames are easy and quick to assemble, wastage is eliminated.

- The steel frames are easily handled on site, no need for cranes or heavy equipment.

- The Steel frames have pre-punched service holes for pipes, wiring, cables reducing the work time of other trades.

- Easy installation of windows and doors as frames are level & square to the MM.

- Once installed there is no maintenance requirements.

- The External and Internal Steel Frame sections are inter-connected and interlocked and can be easily be removed or reposition if there is a change in the design. This means that remodeling is a much simpler process. You can shuffle around anything, at any time, as required.

Build Speed

- The steel frames are manufactured and assembled off-site, which decreases build time on-site.

- Every Steel frame comes labeled and cut to length reducing work time & waste on site.

- Erecting and Assembly is easy and straightforward using a screw gun.

- The Prefabricated steel frames are straight and true which makes it easier and faster to achieve a high level of internal finish on the walls, floors and ceiling.

- Less time wasted on site adjusting or modifying errors in the design or construction.

- Most superstructures can be erected within weeks.

Strong & Light

- Light gauge steel has the highest strength to weight ratio over other building materials. This means that job site contractors can often carry materials by themselves, whereas; wood, concrete, and brick require more manpower or the use of equipment. This cuts down the workload, which saves both time and money.

- Steel is 40% stronger than wood and approximately 10% of the weight.

Safety

- Galvanized steel resists decay and corrosion.

- Steel will never rot. It is not susceptible to mold or mildew.

- If the structure is located in a wet, moist, or humid area, steel is the best option. This not only improves structural safety but health safety as well.

- Even in natural disasters, steel often holds up better than other materials. Whether it’s a seismic event or wind, steel structures survive. Engineered and constructed to be highly resistant.

- At our Factory we implement Stringent Quality Control / Quality Assurance Checks to ensure all frames are produced accurately and to specification.

Overall Savings.

- Many of the previously mentioned advantages make steel a more cost-effective building material. It’s lightweight, high-quality, durable, easy to transport, and resistant to many damaging scenarios. You don’t need to waste money adjusting things on-site as everything is made to order.

- Labour Costs are significantly reduced as the building is erected within weeks, approximately 50% less time than other building scenarios. Reduce Building time results in less labour over the period resulting in tremendous savings.

- The Insulated super structure makes it 60% Cooler than Conventional Construction.

- Clean Job Sites at all times

- Sustainable for a Lifetime, 100 years Durability.

Resistant

- Fire Resistant.

- Termite and insect resistant.

- Steel will not rot, mold or mildew.

- Moisture and Weather Resistant.

- Corrosion Resistant Material – G90 Coated

Environmentally Friendly

- Less Waste.

- Steel is environmentally friendly and recyclable.

- Steel is non-combustible; it will not ignite and contribute nothing to a fire.

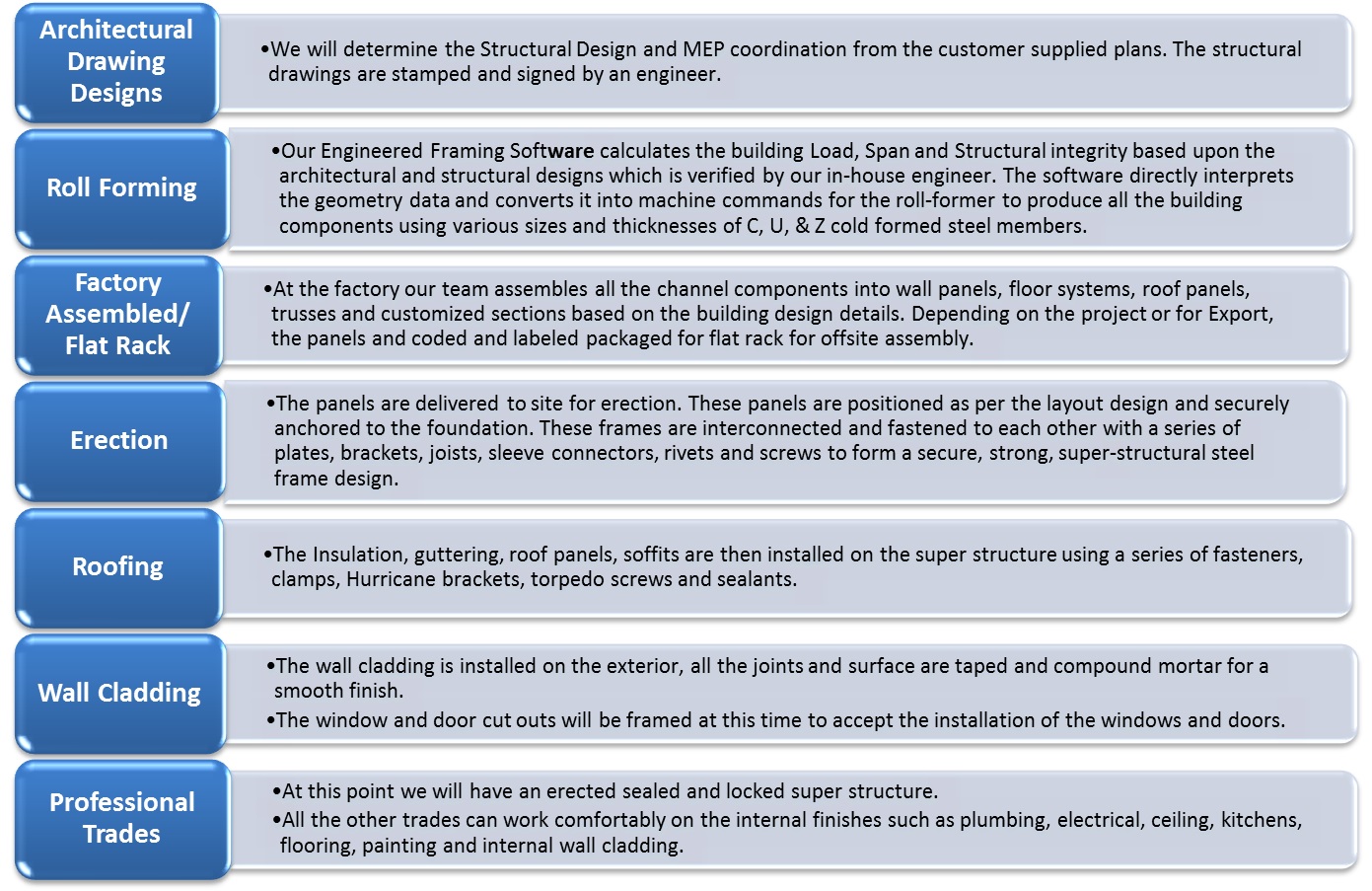

OUR BUILDING PROCESS